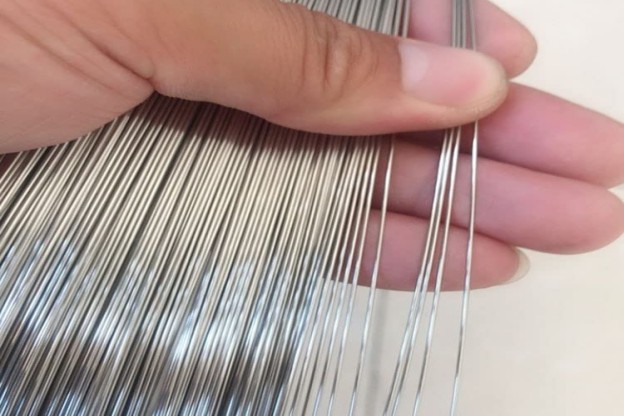

GI binding wire, also known as galvanized iron binding wire, is a commonly used metal wire in the construction industry for tying steel bars together during the construction of reinforced concrete structures. GI binding wire is made of high-quality low carbon steel and coated with a layer of zinc through the galvanization process. Our clients in the Middle East purchase BWG20 and BWG21 GI binding wire from us every quarter.

DESCRIPTION

We specialize in manufacturing and supplying various GI binding wires made from low carbon steel Q195. Our binding wire includes electro-galvanized wire and hot-dip galvanized wire, commonly used in construction and industrial applications. We offer binding wires in different specifications and thicknesses ranging from 8 to 22 Gauge (0.7mm-4.2mm).

Popular sizes of GI binding wire include:

14 gauge

16 gauge

18 gauge

20 gauge

21 gauge

22 gauge

Galvanized binding wire is known for its softness, good ductility, and high strength, making it easy to bend and tie in knots. Through heat treatment, galvanized binding wire gains higher strength and becomes softer. The zinc coating provides resistance to corrosion, giving the wire a matte or shiny finish and protecting it from environmental effects.

For more information on GI binding wire, or to find a supplier that meets your needs, contact us today. Our team can help you select the best type and gauge for your specific application, ensuring you get the most out of your investment.

| Material | Low carbon steel Q195 |

| Type | Electro galvanized wire & hot dipped galvanized wire |

| Gauge | 8 - 22 (0.7mm-4.2mm) |

| Package | in rolls; plastic film inside, woven bag or hessian cloth outside. |

| Weight | 1kg/coil,10coils/bundle; 5kg/coil; 6kg/coil; 10kg/coil; 25kg/coil; 50kg/coil... Any kg/coil you required |

| Application | Widely used in weaving wire mesh, redrawing, products packing, handcraft, binding for construction and daily use. |

GI binding wire in 10Kg rolls of 20 gauge is commonly used in metal mesh processing, binding reinforcement for slabs, beams, columns, walls, etc., in concrete construction. It provides a secure grip for supporting bars of various widths.

In the installation of barriers and fences, binding wire is used for making springs, cables, ropes, nails, and electrodes. Its combination of strength and flexibility is crucial for reinforcing different components of structures and fortifying roofs.

Used across various sectors for packing finished goods, galvanized iron wires are flexible enough to meet various application needs while maintaining high tensile strength to prevent breakage.

Annealing ensures that the wires remain soft for easy handling, assisting in pouring concrete into molds without dislodging the rebars and ensuring secure secondary frame designs.

Galvanized iron binding wire finds extensive use in tying applications in the building and construction field.

Galvanized Iron Binding Wire Size

| Wire Gauge | SWG (mm) | BWG (mm) | AWG(mm) |

| 7# | 4.47 | 4.572 | 3.665 |

| 8# | 4.06 | 4.19 | 3.264 |

| 9# | 3.66 | 3.76 | 2.906 |

| 10# | 3.25 | 3.4 | 2.588 |

| 11# | 2.95 | 3.05 | 2.305 |

| 12# | 2.64 | 2.77 | 2.053 |

| 13# | 2.34 | 2.41 | 1.828 |

| 14# | 2.03 | 2.11 | 1.628 |

| 15# | 1.83 | 1.83 | 1.45 |

| 16# | 1.63. | 1.65 | 1.291 |

| 17# | 1.42 | 1.47 | 1.15 |

| 18# | 1.22 | 1.25 | 1.024 |

| 19# | 1.02 | 1.07 | 0.912 |

| 20# | 0.91 | 0.89 | 0.812 |

| 21# | 0.81 | 0.813 | 0.723 |

| 22# | 0.71 | 0.711 | 0.644 |

Packaging & Delivery

RELATED PRODUCTS